Concentrator

Model: 7028-CONC-001

Application

Used in active waste facilities , research establishments, nuclear facilities, and fusion laboratories for removing tritium from light or heavy water and concentrating into reduced volumes. The product is useful for reducing stored volumes of tritiated water, or for use with an isotopic separation system for removing tritium completely and storing safely on getter beds.

Features

-

Concentrate tritium in light or heavy water

-

Automatic operation

-

Continuous process

-

Minimal operator participation

-

Low pressure and temperature

Description

The concentrator is part of a system to remove tritium from water. It starts with purification to make sure the water is suitable for the next stage in the process. An electrolyzer converts the water to hydrogen and oxygen gas; and the hydrogen, containing the tritium, is collected separately and is passed through the concentrator. Here tritium rising with the hydrogen isotopes in the concentrator columns is transferred to descending water, resulting in higher concentrations in the bottoms water. Tritium-free hydrogen is released. Increase in tritium concentration of 1000 times or more can be achieved. In the case of heavy water the released deuterium gas will be recombined with oxygen to produce clean heavy water.

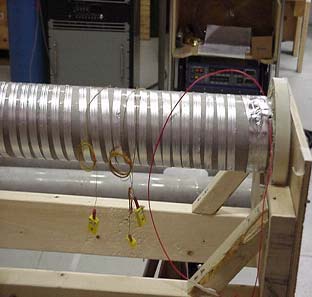

10 mm Column during assembly

Further treatment involves recirculating the concentrated tritiated water through the electrolyzer, and separating tritium from the gaseous hydrogen isotopes in an isotopic separation facility. The isolated tritium can be stored on getter beds.

Glove box located at base of concentrator

The tritium concentration facility cannot be used without an electrolyzer, which is an integral part of the process, though it may be used independently of the isotopic separation system (ISS). The ISS is only required if full separation and storage of pure tritium on getter beds is a requirement.

100 mm Concentrator during assembly

To date Tyne has manufactured 37.5 mm dia and 100 mm dia columns for both light and heavy water. The stainless steel columns are about 30 meters in overall length. The column pumps, valves and automatic controls are operated from a glove box located at the base of the columns. The larger columns process heavy water at the rate of about 100 cc/min. Maximum system temperature is about 60°C, at atmospheric pressure. The unit processes up to 5 tons of heavy water per year. Greater quantities could be handled in larger scale systems.

View of 100 mm column installation before weather proofing is added

Please call to discuss individual customer requirements.

Specifications

| Design | Custom designed to Clients specifications |

| Piping | ASME Section VIII Div 1 vessels |

| Pressure Vessels | ASME B31.3 piping systems |

| Processing | Heavy water or light water |