Tritium Extraction and Heavy Water Upgrading

Application

Used in active waste facilities , research establishments, nuclear facilities, and fusion laboratories for removing tritium from light or heavy water and concentrating into reduced volumes. The product is useful for reducing stored volumes of tritiated water, or for use with an isotopic separation system for removing tritium completely and storing safely on getter beds. The system can also be used for heavy water upgrading.

Tyne Engineering has designed and built various sizes of tritium extraction plants including a small laboratory unit designed for tritium levels of up to 1000 Ci/L; a demonstration scale plant with 1m³/h hydrogen throughput; a commercial plant in Texas designed for 10m³/h hydrogen throughput, and a large scale design for a nuclear facility designed for 150m³/h hydrogen throughput.

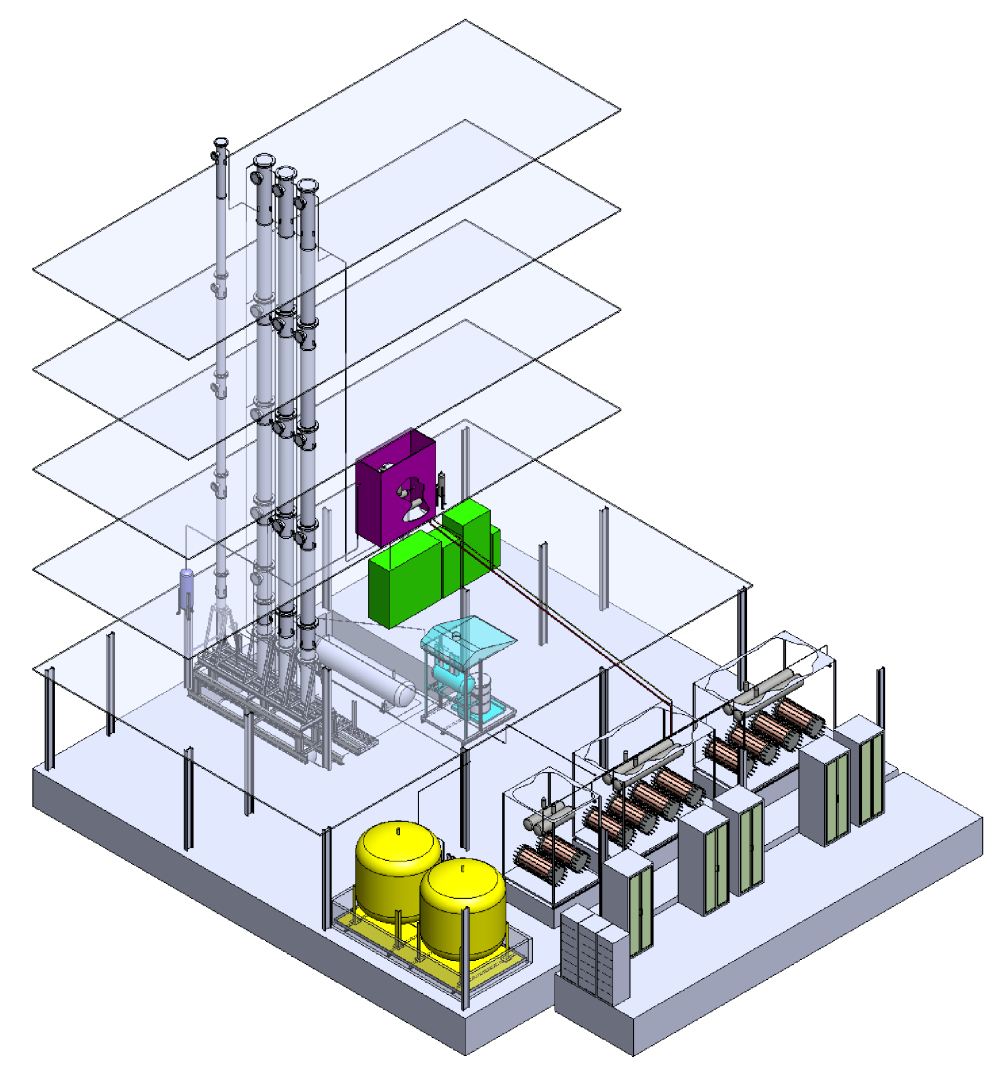

150m³/h hydrogen, 600Mg/annum Light Water Detritiation designed to Nuclear Standards

In all of the above plants, Tyne performed detailed design, manufacturing, and commissioning of key systems including gloveboxes using Tyne's proprietary tritium-compatible seals, tritium monitors and ion chambers using Tyne's own design, electrolyzer subsystem, oxygen hydrogen recombiners, exchange columns, and control system, etc.

Tyne has co-authored a number of scientific papers on the above plants as well as others such as for large scale light water detritiation for Fukushima. An example is this link to a paper on the commercial plant in Texas for which Tyne performed detailed engineering design and manufacture of all major subsystems, as well as programming of the control system, and installation and commissioning of the plant.

Tyne continues to improve the design and is currently developing an improved tritium-compatible electrolyzer which will improve performance and reduce maintenance costs.

Features

-

Extract tritium from light or heavy water

-

Upgrade heavy water

-

Nuclear or commercial pressure code compliance

-

Turnkey design and build solution

-

Automatic operation / Continuous process

-

Low pressure and temperature

Tritium-compatible electrolyzer modified for service by Tyne

Description

The concentrator is part of a system to remove tritium from water. It starts with purification to make sure the water is suitable for the next stage in the process. An electrolyzer converts the water to hydrogen and oxygen gas; and the hydrogen, containing the tritium, is collected separately and is passed through the concentrator. Here tritium rising with the hydrogen isotopes in the concentrator columns is transferred to descending water, resulting in higher concentrations in the bottoms water. Tritium-free hydrogen is released. Increase in tritium concentration of 1000 times or more can be achieved.

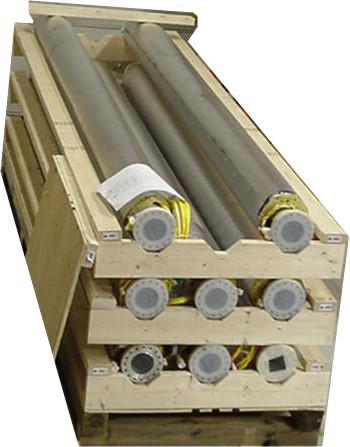

LPCE columns designed and fabricated by Tyne, ready for installation in Texas

In the case of heavy water the released deuterium gas will be recombined with oxygen to produce clean, upgraded heavy water.

Oxygen Hydrogen reccombiners, designed and built by Tyne are used in some configurations

Further treatment involves recirculating the concentrated tritiated water through the electrolyzer, and separating tritium from the gaseous hydrogen isotopes in an isotopic separation facility. The isolated tritium can be stored on getter beds.

Isotopic Separation System designed and manufactured and commissioned by Tyne - ready for installation in Texas plant

The tritium concentration facility cannot be used without an electrolyzer, which is an integral part of the process, though it may be used independently of the isotopic separation system (ISS). The ISS is only required if full separation and storage of pure tritium on getter beds is a requirement.

Getter Beds designed and fabricated by Tyne, can be used for permanent immobilization of tritium for long term, safe storage

To date Tyne has manufactured 37.5 mm dia and 100 mm dia columns for both light and heavy water. The stainless steel columns are different lengths depending on the degree of separation required. The column pumps, valves and automatic controls are operated from a glove box located at the base of the columns.

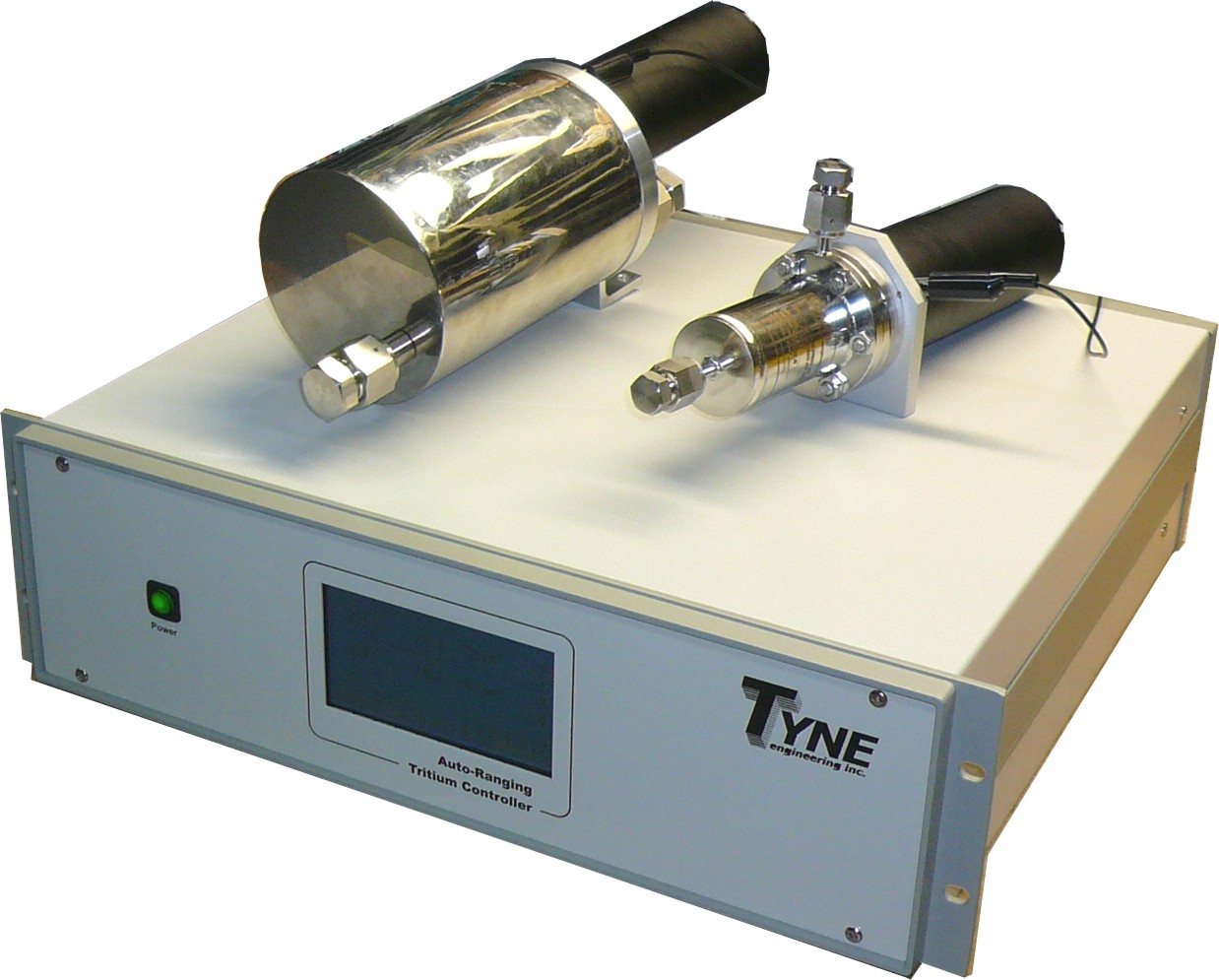

As the manufacturer of the main sub systems and most of the specialized equipment, like the tritium monitors shown, Tyne can provide turn-key tritium extraction or heavy water upgrading solutions.

Tyne's ionization chambers and tritium monitors are used at various locations in the process

Please call to discuss individual customer requirements.

Specifications

| Design | Custom designed to client specifications |

| Configuration | Skid-mounted modules for shorter schedule and better quality control |

| Pressure Codes | ASME B31.3, ASME Section VIII Div 1 vessels, or Nuclear N285 /ASME sec III depending on the installation location/facility. |

| Processing | Heavy water or light water |